Solder also contains toxins if heated too heavily, so you want to ensure your heat gun is at the correct temperature before starting. A heat gun is a relatively inexpensive method to heat solder paste onto your components and the board however, it still can get quite hot, and thus you need to be careful while handling it. Reflow soldering is done on a smaller scale. When you require bulk soldering, which involves many circuit boards in a short period, wave soldering is the most efficient method. Both have benefits depending on your project. There are two ways of soldering: wave soldering and reflow soldering. Soldering is very important during the PCB design process it’s the only way to adhere circuits to your board. What is the difference between reflow soldering and wave soldering? Reflow Soldering

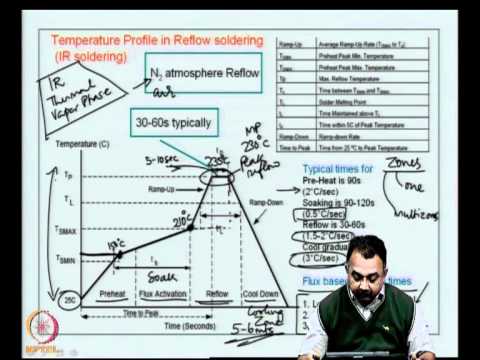

Use controlled heat to reflow the solder paste into a molten state this creates permanent solder joints. Solder paste, a mixture of powdered solder and flux, attaches many small electrical elements to a contact pad. Reflow soldering is a process that involves attaching surface mount components to a circuit board (PCB).

0 kommentar(er)

0 kommentar(er)